Narita East Logistics Center(ELC)

About our facility

- Address: 245-113 Taragai Narita-City Chiba-Pre,Japan

- Totally area: 263663sq.ft.

- Location: along Prefectural road(Kendo-mainly rural road)44 【Narita airport area to Kashima port in Ibaraki-Pre】

- Access: 6.4km from Narita IC/5.3km from Taiei IC at Higashi kanto Expressway

1.0km from Taiei IC at Ken-O Expressway

3.9km from Narita International airport second gate

3.8km from JR/Keisei line Narita International airport terminal 2 station

Facility introduction1

Freezer / Refrigerator / Air conditioner / Dangerous goods storage (Bonded warehouse)

Effective depth 6.5m

Freezer(-30dgree) 2065sq.ft.

Refrigerator1(+5dgree) 3184sq.ft.

Refrigerator2(+5dgree) 1936sq.ft.

Refrigerator3(+5dgree) 2593sq.ft.

Refrigerator4(+5dgree) 2367sq.ft.

Air conditioner(+20dgree)

5043sq.ft.

Dangerous goods storage(flammable liquid)

1097sq.ft.

It's passible to pack items with adjusted temperature inside of each warehouse.

It's allowed to report temperature notes of preserved items for administration unit.

CAD style Cutting machine

Installing the newest cardboard/double stuck pallet cutting machine

Just fit size for items

Weight light than further

Needless cushioning materials

Save deadline and packing time

All weather type distribution center

Usually, vehicle enter from vehicles entrance and delivering items each area

Whole warehouse, all area covered by roof

Low damage risk each cargo even if stormy weather

Designed large size of eaves at east side of center

【Height6.5m×depth13m×width125m】

Facility introduction2

Emergency electricity back up system

Work for office building, freezer, refrigerator and electricity inside of warehouses back up

Capacity:12h/1,150L

Fuel stock:3,000L

Continue to work if supply to fuel

Automatically calibration device

Installing the newest one

Measure and scale

Serving accurately size and weight items for our suppliers

Originally job procedure program

Sharing all job procedures with whole staff of center

Collaboration working with automatically calibration device

Use tablet in work-site

Showing cargo information with images

Security Measures1

To ensuring an against terrorism of cargos, food defense (Which is the effort to protect food from acts of intention adulteration), we have erected an X-ray device and explosive inspection machine.

X-ray Device

| 638DV |

: made by Rapiscan System : air cargo qualified by TSA (The Transportation Security Administration)

|

|---|

Explosive inspection machine

ItemiserDX made by Rapiscan System : air cargo approved by TSA (The Transportation Security Administration)

Simultaneously detects positive and negative ions using a single detector. Maintains a low,stable humidity level in the detector, allowing for consistent and reliable detection results.

Security Measures2

A Metal Detector

We erected the metal detector at the janitor's room and entrance for both employees and visitors to probe any suspicious stuff.

Security Cameras

We have struck hands on the contract with SECOM.

We have not only 60 camera surveillance systems but also secure any suspicious person for 24 hours a day.

For employees

Only employees who have an ID card are able to entre and exit the offices and warehouses.

Security Measures3

Office and warehouse doors

We should protect to our client's merchandise, company’s private information, safety measures and environment or any other concerns…

However almost of all office doors and warehouse doors are STEEL DOOR.

The biggest advantages are strength, durability and security.

Those three features perform fire resistance, sound reduction, vandal resistance and sanitation.

We promise keep confidentiality with clients and that is just a non-negotiable essence to ensure client's merchandise safely

Window glasses and entrance double door

Window glasses

We adopting tempered glass for windows.

Tempered glass surprisingly does not spread and when shattered into hundreds of tiny pieces are not sharped.

Also, they have 3-5times strength than standard glasses for some impacts.

It seems to be not broken by hummer. Harmless!!

Double-entry doors

This is one of our security aspect part.

Our mainly guests entrance door is unique design for protect safety.

There are two doors-outside and inner side, and they work one by one.

When inner side door open, then outside door will be lock automatically.

If someone suspicious people come into our building, we will not let them go.

Reference 1

Hygiene Management

Especially, timing of the infection spread COVID-19, we consolidate a measure a disinfecting device and tire washer at the gate to prevent getting an epidemic

Dust-resistant design

- High-Speed Roll-Up Door has been installed. Every vehicle drives indoors.

- All windows are made by shatterproof glasses and there do not open (A single piece of glass).

- It has been put bloating agent at the joint between exterior wall and roof in order to prevent insects and dust from entering.

Fire prevention

Compartmentation each warehouse to prevent of fire spreading as a pre-Salamandrine.

Installed fire hydrants and asphyxiators

A fire cistern 40kl x 2

Reference 2

Low power consumption

Our facility has been unified with LED lighting device so that could cut power consumption by 90%.

Also we succeed to cut power consumption by 30% due to the refrigerator and freezer got the newest equipment.

Solar photovoltaic power

The roof has 4816 solar photovoltaic panels to prevent runaway global warming and release CO2. (250w x 4816 panels = 1200kw)

In the case of a blackout, we will be able to secure stable electric power for freezer,refrigerator and any communication device due to a power plant of its own.

※Which means cover the cost associated with 400 common household in a day

Roof at the main branch

Our Strengths

when natural disasters strike

First of all, there is a lot of heavy equipment, chemicals, and plenty of tall shelves which are fully stocked with merchandise. Earthquake happens a lot of time a year, also huge earthquake happens once or twice every few years in Japan. Earthquake will always pose a danger to people inside buildings. At this point, our foundation can resist over 7.0 quake with 250 piles.

Furthermore, there is no concern about ground liquefaction that is one of the influence comes from earthquake. Our foundation is based on concrete and its bearing capacity of the floor will be over 5 ton per 1㎡. It is more than double bearing capacity the other warehouse company.

We could say that it is ideal facility to store items and driving forklifts and trucks.

Moreover, if over 6.0 quake hits, there is a high possibility that it will appear a tsunami. The tsunami causes likely millions of damage to employees, clients and merchandise. However, there is no threat of a tsunami because our ELC warehouse is built at over 131 feet above sea level. Additionally, it is beneficial not being covered with water when it rains heavily.

We will be sure to keep everyone safe and prepare for natural disasters to protect employees and merchandises,

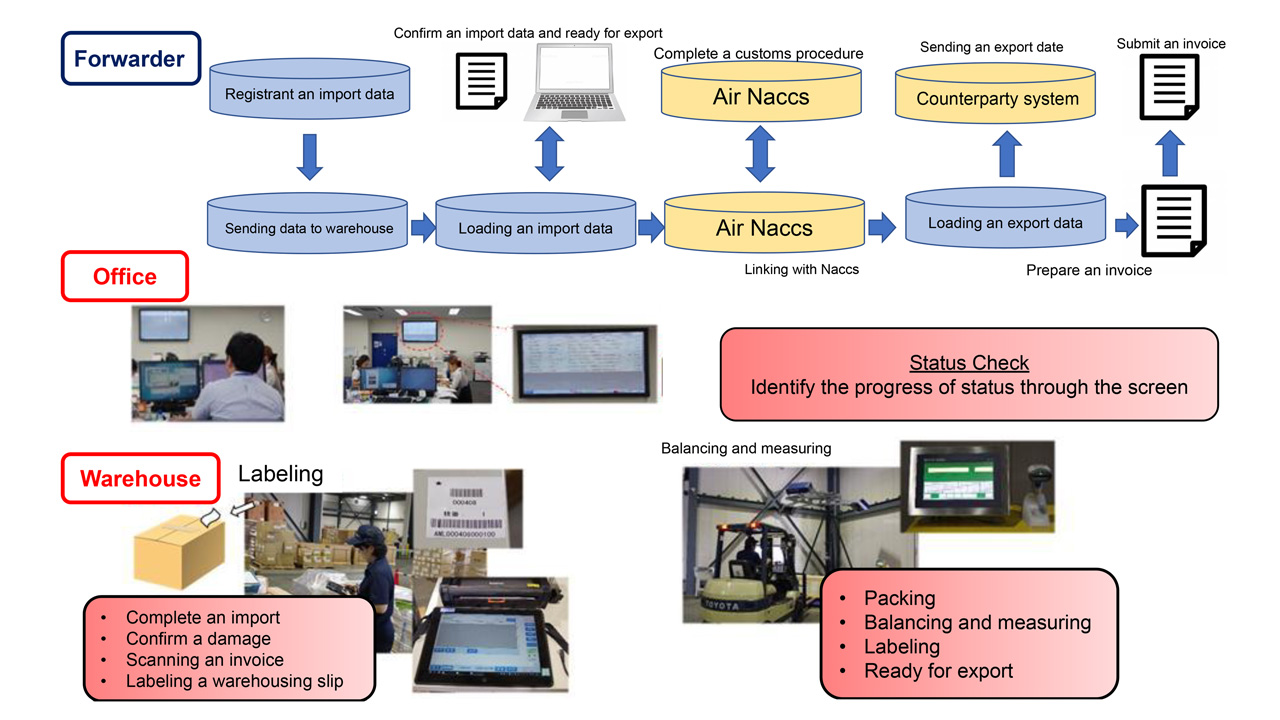

Cargo Operation System

Based on the opinions of local input

The most important things is an accident avoidance.

Some accidents unfortunately have happened before. For example, cross shipping causing injury breaking cargos, and we really apologized for them.

Please accept our apologies for the inconvenience. We have experienced a disadvantaged business in an accident treatment, furthermore there is no end to happen any accidents in logistic business.

Risk management

We have analyzed past occurrence so many times, however there was no answer about why it happens, why we face a prevent. Then, we changed a focus to the field site as the result of that accidents happed at the warehouse. We asked for through management of the operation, health control, hygienic control and let all of them know an operation manual. Furthermore, we have been approaching to create the safety job site with regular coaching to sustain preventing.

Moreover, in order to keep accidents as low as possible, we conduct “crisis prediction management manual” at each warehouse, as a result, our company achieve a large number reduction of accidents.

Crisis management

95% of past occurrence was happened by human error, there is no problem with system.

For example, we had used to check with a few staff inspected slips (for cargo come in/out ) and 8 to 12 numbers over 100 times.

In order to be prepare for human error, we create“Cargo come in/out conducting system” and“WEB cargo conducting system”

Q. Practice Task

- Task1

- S/I used to be done with instructions, will it be a paperless?

- Task2

- Loading/unloading are acted by a few staff with instructions, is it possible to reduce human error and cost of employees?

- Task3

- Would like to know how much it cost for packing, storage at bonded goods area and entering and leaving a warehouse as soon as possible

A. storage shed for air cargo : WEB cargo conducting system

We attempted to invent a new system, WEB cargo conducting system, to reform a checking structure by a few staff.

- Interfacing with NACCS, we scan a cargo label with handy terminal

- Make own number with bar code as each goods arrived.

- Only one person needed to complete those action and make it rapid and accurate.

As the result of that taking those system, it made possible to reduce the number of employee and had a great benefit which is outgo than install fee.

Moreover, we are able to confirm the status of forwarder’s orders at screen and constantly responsethem. Also, if you create an account on our system, you will be able to check your history you used us before.

Of course, you will be able to receive the information you need by our EDI system smoothly.

Our New Dangerous Goods Warehouse

Certified by Tokyo custom as a dangerous bond warehouse.

Recently, Chemicals are playing an important role and presenting in different form into our lifestyle. There are lots of regulation to manage, transport and store, at the same time, they are asked a safety and reliability for environment conservation.

Therefore, we have built Dangerous Goods Warehouse which is licensed in accordance with the regulations to response those compliances.

Asahimori will take care of store and handling!